|

Modern age requires the development of a wide range of active and passive energy devices. Fields of application for them are energy management and power sources, electronics cooling, bioengineering etc. Since the most important fossil fuel reserves are diminishing and exhausting, they are not able to satisfy the demand of modern economics. That is why the utilizing of nature friendly solar energy, wind, biomass fuels and solar energy can be considered as an optimal solution to the fast growing energy demand and greenhouse effect in atmosphere. At the same time it is very important to ensure the efficient consuming of the natural gas in low temperature technologies, converting it to hydrogen. One of the key low temperature technologies is the electrochemical power source, namely fuel cell (FC) that converts chemical energy of hydrogen in coupling with air into electricity and that generates hydrogen and oxygen when it is used reversibly as an electrolyzer.

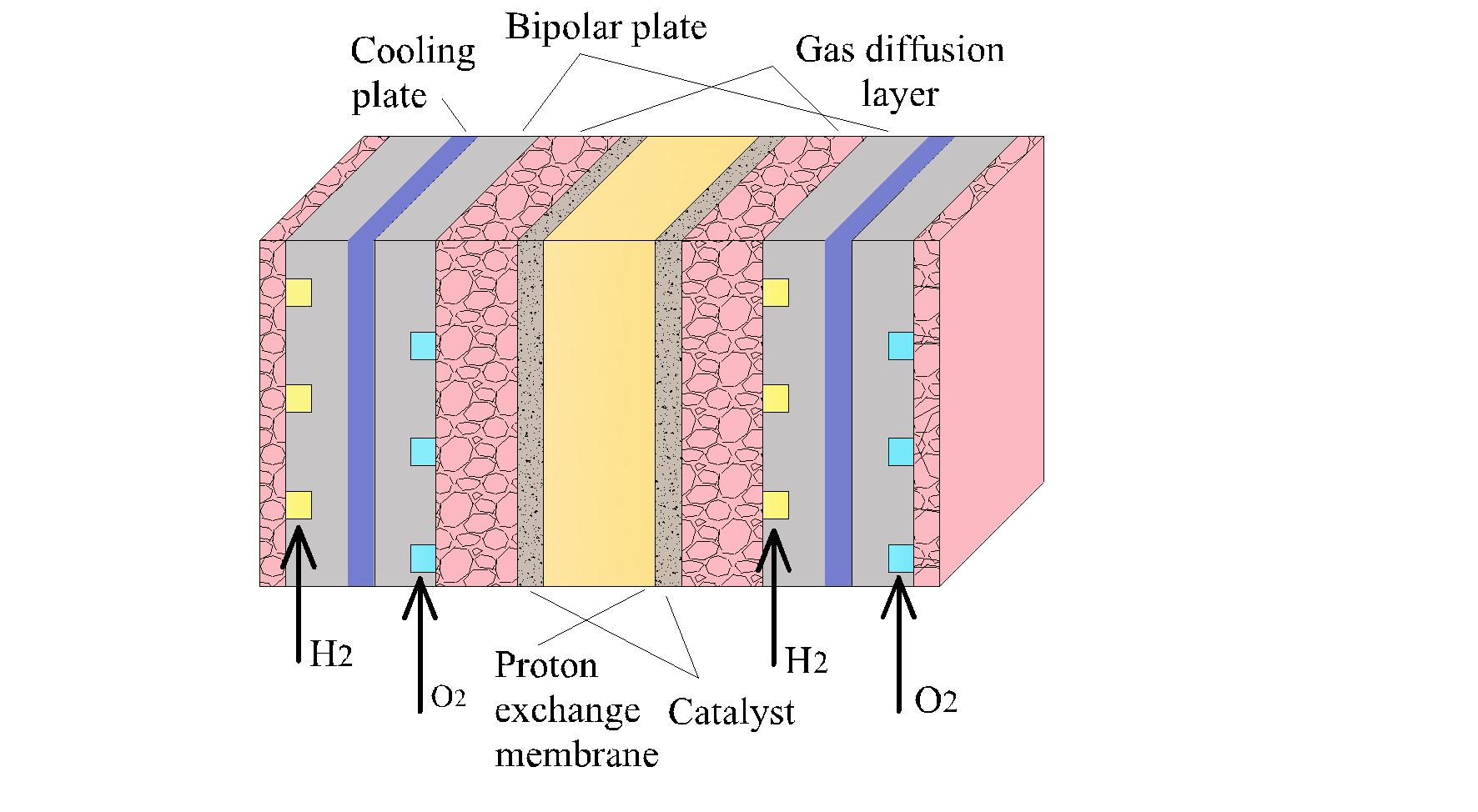

The most efficient and steady functioning of FCs requires ensuring of certain temperature regime, namely determined temperature of incoming reagents, uniform temperature distribution on bipolar plate surface and removal of releasing heat from fuel cells stack. Thermal management on the basis of heat pipes (HP) is able to guarantee these conditions owing to HP’s extremely high thermal conductivity coefficient, low thermal resistance and absence of additional energy consumption. There are several ways of the most efficient thermal management of FCs on the basis of heat pipes:

- Embedding of heat pipes and thermal spreaders (flat heat pipes) into bipolar plate or between FC modules in a stack

- Integration of one part of heat pipes into FC construction

- Using of heat pipe concept (phase change in porous structure) in construction of FC’s gas channels

A wide range of FC constructions gives possibility for their use in different applications including power stations, stationary generators, engines and mobile devices. PEMFC (proton exchange membrane fuel cell), DMFC (direct methanol fuel cell), SOFC (solid oxide fuel cell) and MCFC (molten carbonate fuel cell) had the most distribution in commercial field as most perspective FC types. Depending on power dissipation of FCs different types of HPs may be used, namely micro and miniature heat pipes (1–100 W), loop heat pipes and loop thermosyphons, pulsating, sorption heat pipes (100–1000 W).

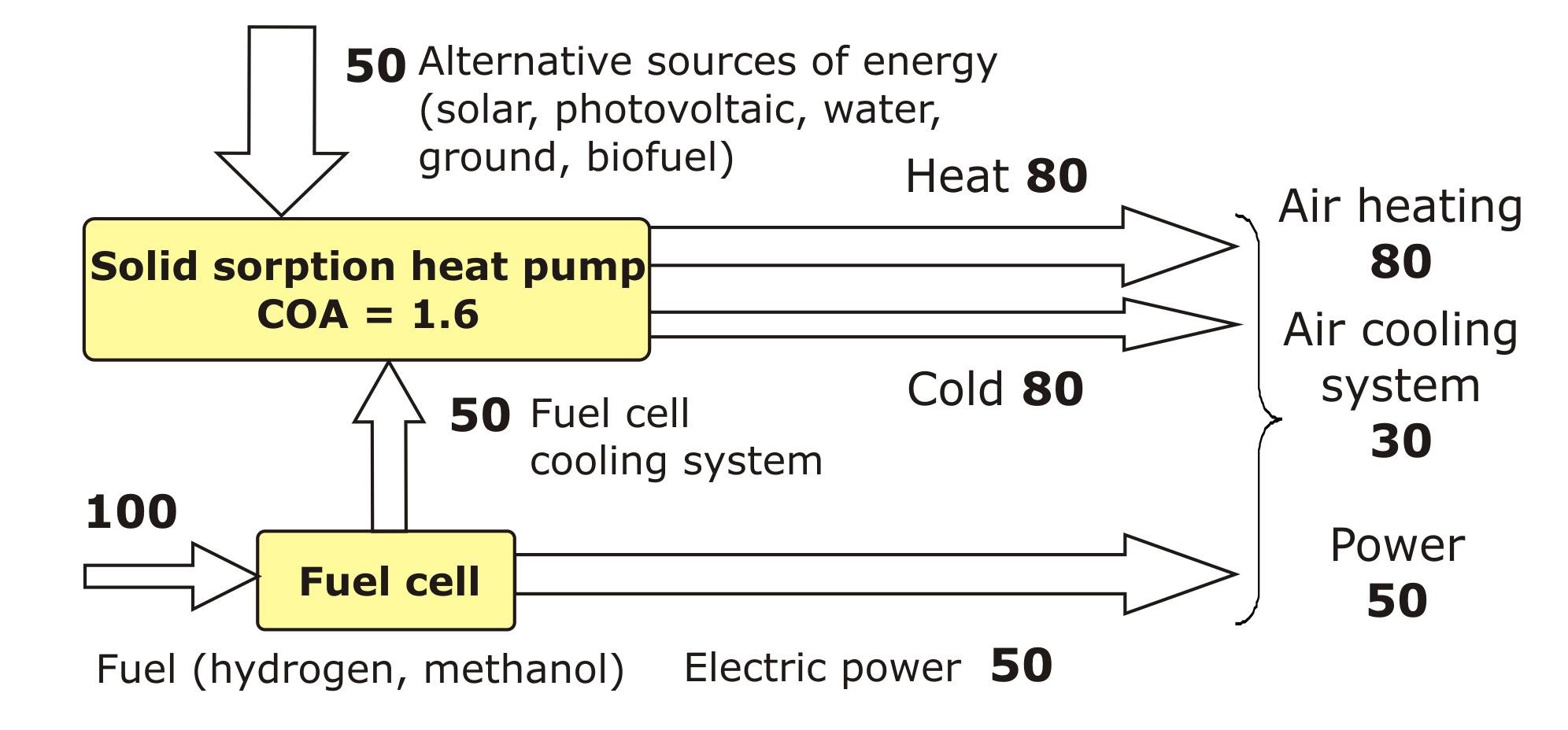

Besides this category of heat pipe application there are possibilities to apply heat pipes in fuel cartridges thermal control. Moreover, potential applications of HPs for fuel cells thermal management include also systems of wasted heat recovery. Heat removal to ambient is the simplest method, but utilization of dissipated heat for power supply of other elements or in some cases for an additional energy production is more advantageous. For example, there is a possibility of combined application of FC and sorption heat pumps in trigeneration system. Alternative (air, water pools, soil, soil waters, solar energy) and secondary energy sources may be used as low potential sources, making such system ecologically safety. Besides, an advantage of sorption heat pump is that for coolant transport electrical energy is not necessary, since its functioning is based on adsorption and desorption phenomena. By use of low potential heat sources, heat pump allows saving up to 30% of primary energy and reducing harmful outputs.

|