|

Evaporative and boiling heat exchange processes are among the promising technologies nowadays and they are widely applied in a power engineering, refrigeration and other branches of a techniques. In particle, a heat exchange at evaporation is adopted in heat pipes and thermosyphons, desorbers of chemical heat pumps, evaporative chillers for components of electronics. To design and improve evaporative heat exchange apparatus it is necessary to know the conformities of phase change heat transfer to natural laws.

An increase of a vapor phase formation activity at low temperature heads is realized most effectively by using of surfaces with a porous coating (sprayed, sintered, deposited), ensuring advanced system of capillary channels, high effective thermal conductivity, being firm and having a sufficiently good connection with a heat exchange surface. In addition, porous structure should resist to erosion and vibration effects and keep stability of all these properties during long time, should be manufacturable and reasonably priced. For these requirements porous structure of sintered copper powder is a promising solution.

Creation of the universal mathematical model of heat transfer at evaporation and boiling in porous structures is highly difficult problem. Moreover, it is hardly possible due to the process dependence on many factors that have a probabilistic or even accidental character. So since theoretical description of evaporation heat transfer in porous structures is rather complicated, experiment is very important in such investigations.

The methodical investigations of a heat transfer at a boiling and evaporation are carried out in the Porous Media Laboratory. Different liquids may be used for these researches, in particular, the heat transfer at a propane (R290) evaporation was studied. Propane was chosen as working fluid because of its good thermodynamic properties, low cost, availability, compatibility with constructional materials, environmental friendliness. The latest circumstance is very important because of the prohibition on ozone depleting CFC and hydrochlorfluorocarbons HCFC applying.

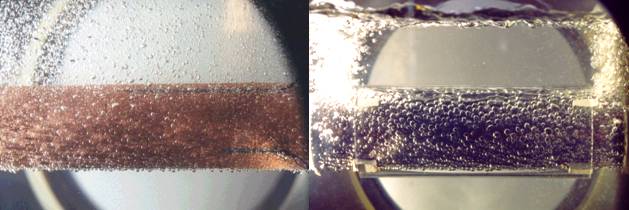

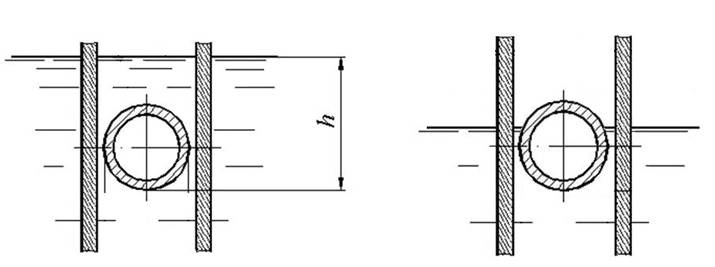

Variations of the conditions of immersion of the tested sample with porous coating in liquid

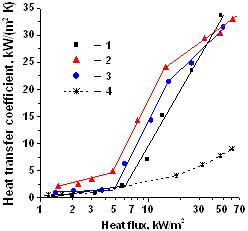

Heat transfer intensity at propane evaporation in porous coating

formed by sintered copper powder. Comparison of heat transfer coefficients

(h=75 mm, tube diameter 20 mm, coating thickness 0.3 mm)

on porous (1-3) and smooth (4) tubes:

1 – liquid pool, 2 – annular mini-chanel, 3 – side gap, 4 – smooth tube

Obtained experimental results allow to conclude the following:

- a thin sintered copper powder structure with micro heat pipe phenomena stimulates the evaporative heat transfer nearly 8–10 times higher than propane pool boiling heat transfer on a smooth horizontal tube,

- the two-phase heat transfer in an annular mini channel with stable propane bubble generation on a thin (0.3 mm) porous surface of the heat releasing tube stimulates the Marangoni convection and enhances heat transfer 2–3 times as compared to the same tube heat transfer in a liquid pool without additional power supply (no mechanical pumping),

- evaporative heat transfer inside a porous structure + two-phase forced convection in an annular mini channel points to the availability of a thermodynamically efficient mechanism of cooling the semiconductor components, space thermal control, aircraft devices, traction drives, and audio amplifiers,

- cooling devices based on the heat transfer process inside a porous structure + two-phase forced convection in mini/micro channels are of interest for micro- and optoelectronics fields.

Intensification of heat transfer process by using of enhanced heat transfer surfaces leads to sufficient reducing of energy consumption of electronic equipment, its weight and size.

Visualization of the hydrodynamic and heat transfer of heat releasing tube with porous coating, disposed inside the annular mini-channel, propane, q=34 kW/m2.

The aims of investigation are next:

- Searching for new methods of two-phase heat transfer for microelectronics and optoelectronics requests.

- Widening of overview of heat transfer mechanism at evaporation in porous structures.

- Studying of the influence of combination mini- and micro scale effects on heat transfer processes at confined space at liquid evaporation in porous structures.

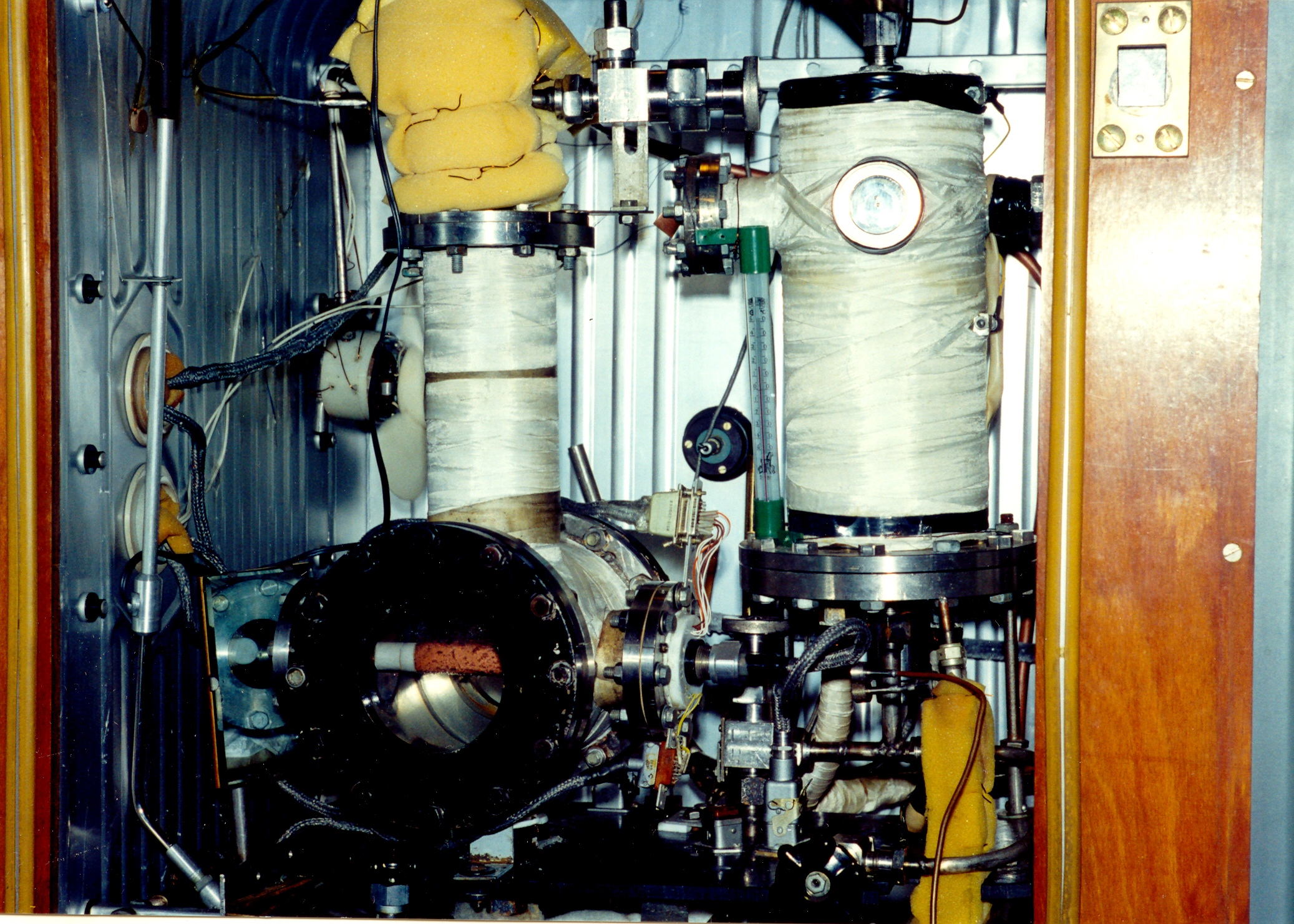

For this purpose the experimental setup was designed and performed. It consists of a test vessel, an insulated vacuum chamber with thermally controlled liquid guard circuit, cooling machines (refrigerators), thermostats, a temperature control system, a vacuum pump, a liquid flow meter, and a liquid circulation system. A data acquisition system with a set of thermocouples was installed to transfer the information to a computer. The temperature measurements are performed in a steady-state regime.

|