|

Vacuum sorption drying of fine wood (oak, Karelian birch, etc.) and timber by heat panels is a new energy-efficient, environmentally appropriate technology, which provides quality, high speed of the drying process, and minimal costs of fuel.

Internal heating of wood by heat pipes, namely, heat pipes–heat panels, and regulation of wood humidity with use of sorbents form a novelty of the proposed drying technology. A gas burner or solar radiation is the potential source of nonelectrical energy for drying process realization.

The main components of an installation for vacuum conductive-sorption drying are the vacuum chamber and sorption and heating panels.

Sorption panels provide high-precision regulation of saturated vapor pressure inside the chamber by regulating the sorbent temperature. Drying with the use of sorbents is energetically more favorable comparing with other techniques of materials drying.

While heating the sorbent by heat pipes in desorption a sorption panel is being used as a steam generator, whereas in adsorption it serves as a vacuum pump, that absorbs moisture vapors and noncondensable gases inside a vacuum chamber. At the same time, electrical energy is being saved for vacuum pump drive and the possibilities of environment parameters regulation inside the vacuum chamber become wider.

A system of sorbent heating and cooling by means of heat pipes has significant advantages over traditional apparatuses for drying as far as there is no necessity for application of pumps for pumping intermediate heat medium. Owing to a number of unique properties of heat pipes, dimensions and mass of heating panels are reduced considerably and their exploitation characteristics are improved. The proposed drying technology of materials inside the vacuum chamber by using sorption and heating panels with thermosyphons provides minimal fuel expenditures since internal heat supply is realized at high isothermality of surfaces of these panels.

Main benefits of a vacuum sorption wood drying installation

The apparatus for vacuum conductive-sorption drying uses inexpensive energy sources such as gas burner, secondary energy resources, solar energy The apparatus for vacuum conductive-sorption drying uses inexpensive energy sources such as gas burner, secondary energy resources, solar energy

There is a possibility of realizing a closed power cycle with utilization of sorption and condensation heat for hot water production and rooms heating There is a possibility of realizing a closed power cycle with utilization of sorption and condensation heat for hot water production and rooms heating

Material drying is carried out at a reduced temperature, with accurate maintenance of temperature and humidity regimes, that ensures high quality of the end product Material drying is carried out at a reduced temperature, with accurate maintenance of temperature and humidity regimes, that ensures high quality of the end product

Heat pipes secure maintenance of uniform temperature and humidity fields within the timber pile, and the probability of local overheating and deformation of dried objects decreases Heat pipes secure maintenance of uniform temperature and humidity fields within the timber pile, and the probability of local overheating and deformation of dried objects decreases

Internal heating of the pile allows maximum efficient use of the set heat power Internal heating of the pile allows maximum efficient use of the set heat power

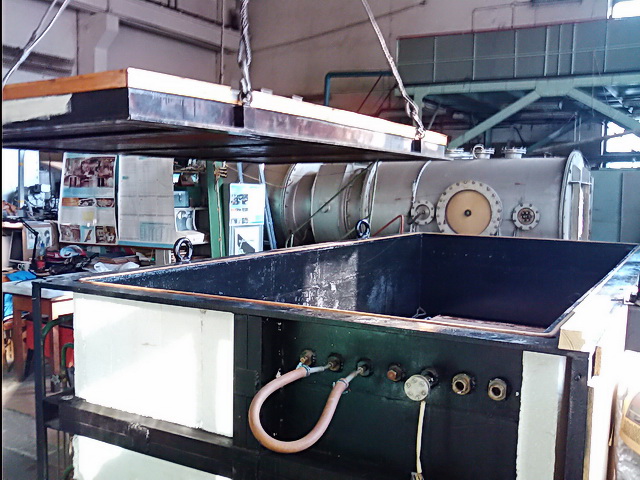

Vacuum chamber of the drying installation  | Main technical characteristics of the installation

Overall dimensions (internal) of the vacuum chamber:

length, m

width, m

height, m

Overall dimensions of a pile:

length, m

width, m

height, m

Overall dimensions of a timber pile with heat panels, m3

Vacuum intensity, MPa

Set heat power, kW

Working temperature of heat panels, 0С

Surface area occupied by the installation, m2

|

3.7

1.7

1.0

3.0

1.4

0.7

2.84

0.045-0.060

30

30 - 70

100

|

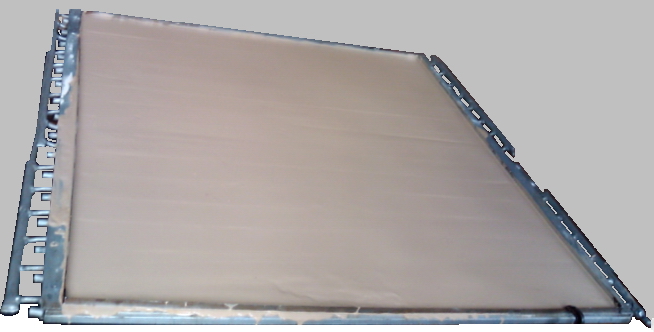

Timber pile with heat panels – heat pipes

|

Sorption panels – heat pipes |

|